|

Forward Gears Performance 5 speed in your vintage Volvoby sberryThis article was written in March, 2007. I've done a lot of power adding activity under the hood my 1971 Volvo 1800E. Behind the stronger engine I've been shifting a 'good used' M41/OD transmission using a Clutchnet 6 puck sintered disk. This power is transferred to the ground through a stock 4.30 rear gear with a Detroit truetrac limited slip differential driving 205/55/16 tires. The venerable M41 gearboxes are actually pretty awesome synchromesh boxes and will typically go for hundreds of thousands of miles without complaint even with seriously jacked up engine output. This car is used for a lot of autocross competitions. This involves driving the car as quickly as possible through courses marked by cones laid out in parking lots. While speeds rarely exceed 70mph the courses are extremely technical and demanding on the car and driver. Dropping the no-slip clutch off the line and redlining 1st and 2nd gear to snake the car through cones takes a toll on a 40 year old transmission no matter how much revmatching and synthetic lube you throw at it. The M41's 2nd gear synchros slowly started deteriorating - manifesting as aggravating crunching when trying to downshift into 2nd for turnoffs in normal driving. After a while it was impossible to rev out 1st gear because upshifts to 2nd gear would balk unless the revs were under 2500rpm. It was time to start investigating a repair. If you've read any of my other modification articles you can safely predict that this project will spin out of control. Easy choicesThe easiest and cheapest approach would be to rebuild my stock Volvo M41 transmission. The parts are available and I even have a donor box out in my shed. I have faith that a properly rebuilt M41 would satisfy my requirements and outlast the rest of the car. The failure of the current box came after unknown hundreds of thousands of miles followed by combat duty on the autocross course and should not reflect on the durability of the M41. I figured at most a professional rebuild would cost me $1000 and a few hours under the car, doing it myself would probably cost less than $500 and earn me a new automotive merit badge. The Laycock overdrive can be a downside to this transmission. While I love the sensation when flipping the OD switch it is a complicated member of the drivetrain. The parts and expertise to repair them are becoming harder to find and it adds up to just one more thing to break. This, coupled with the fact that fixing the factory setup made way too much sense and posed no fitment or compatibility issues, forced me to quickly dismiss it and look for a more difficult solution. At this point I turned to the internet for accurate information and unbiased opinions on gearbox options. Anthony Hyde has drafted a terrific breakdown of alternative transmission options for RWD volvo motors and reviews the pros and cons of various gearboxes for use in a conversion. He has used a bellhousing made by Dellows (Australian Company) that allows installation of a toyota Supra transmission with Volvo motors. This bellhousing weighs in at ~$400 and would need to be shipped from Australia. He appears to be quite happy with it. I couldn't find much info about other people's p1800 transmission swaps online but Aaron Baker's T5 swap into a 240 and the search box on Turbobricks.com were helpful starting places that steered my decision towards using a Ford T5 5speed as well as a lot of useful info for the swap. This transmission can be bolted up to my car using an adapter plate sold by Vintage Performance Developments in NY - the same company that makes my supercharger kit and ported my cylinder head. John sells a custom machined adapter plate used to connect the transmission to the stock Volvo bellhousing as well as some custom spacers used on the clutch fork to attach a Ford throwout bearing. NOTE: Making a T5 swap into an earlier (pre 1970) p1800 will mean modifying the narrower transmission tunnel - these cars cannot accept a T5 transmission without doing this. There is a great aftermarket for the T5 transmission and it is likely the most common choice for these types of swaps (particularly amongst older Fords). Clutches, shifters, speedo stuff etc. are all very available. This box is also very common in roadracing applications so getting upgraded internals is no big deal. The desirable ones could handle greater torque and were installed mainly in V8 mustangs. These T5's bear the 'World Class' designation. You can find more general info about the T5 on John's site and at Modern Driveline. I set my conversion budget at $1500 and plowed ahead into the parts gathering phase. How to pick a T5I needed to get a World Class T5 out of a late 80'/early 90's mustang (v8). These gearboxes should be able handle way more horsepower than I can crank out of the B20 on pump gas. I started out by looking locally, calling car-guy friends, transmission shops and used parts places. Most of the stuff I'd read on the internet indicated people were finding decent used boxes at the salvage yard for a couple hundred dollars. No luck for me here in Charlotte, NC. The T5 boxes get gobbled up pretty quickly by the numerous circle track guys. My next source was ebay - there were lots of people selling T5's on ebay at such varying pricepoints and shipping schemes I could not decide which sellers were legit - confusing enough to make me pass over the whole lot of them and start looking into well known individual retailers/rebuilders. Alternatively - there are videos and quality rebuild kits that can be had from ebay and other sources that may save a lot of dough if you can find a core gearbox to work with. The longer I looked the higher my pricepoint began edging until I was down to deciding between a rebuilt unit from modern driveline (~$950) or coughing up the cash for a brand new Ford Motorsport transmission from the Summit catalog (~$1,300). Once you narrow down some vendors you can start analyzing the various gearing options available. 5th gear has a wide variety of possible configurations ranging from .63 overdrive to .80 overdrive (very big difference!). Here is a little table I made to analyze the gear ratios of the transmission options - I like to cruise at 80-85mph on the higway. The MPH figures take into account my 205/55/16 wheel/tire combo, a 4:30 final drive ratio and a redline of 6500rpm. Here is a great driveline calculator if you want to work out your own figures:

Unless you are on a track with a very long straight or you have outrageous horsepower, 5th gear/OD is only a player in highway cruising scenarios. I talked quite a bit with John regarding his experience with the various setups - his inclination was that the .63 ratio is too tall - he found that his mileage actually suffered because the long gear forces greater throttle openings at moderate cruising (all dependent on final drive ratio and wheel diameter) and that a shorter ratio would be better for highway passing - ideally the original Volvo OD ratio of .80 would be perfect. .80 ratio "road racing" gearsets are available from various sources but they would add at least $300 to the price of the transmission once labor was factored in. With the increased power in my 1800 I was thinking the Ford Racing transmission would have been OK with the long OD gear. Additionally, the slightly longer 1st gear could be very cool for autocrossing (delaying that 1st shift as long as possible). I decided to go with the standard Ford ratios more due to price than anything else. The Ford racing trans. would have cost $1500 by the time it got to my door and nuked the whole original budget with one swipe of the credit card (later to be nuked anyhow). I ended up sourcing a performance rebuild from D&D Performance in Michigan. They shipped me a T5 with upgraded first gear set and strengthened cluster gears along with a 6 month warranty for $1064 delivered. It showed up at my door less than a week after ordering (I was very pleased with D&D overall). In my ClutchesWith this conversion you have a lot of options for clutch/pressureplate setups. You need a Ford clutch disk with the T5 spline count of whatever composition/grip you want. The pressure plate will need to be compatible with your Volvo flywheel and the stock PP is your best bet unless you are making tons of power. I've had experience with a few different discs on my B20. My first clutch was a stock Sachs unit. I never had any problems with it but when my first transmission went I upgraded to a grabby 6 puck clutchnet clutch in anticipation of the supercharger. The sintered clutchnet part would not slip at all and was pretty rough in everyday traffic - trying to slip it uphill out of the bank parking lot for instance. Although I got used to it and kind of liked it after a while I would avoid this sort of clutch unless you have a very demanding application and a limited budget. I decided to try using a friendlier clutch coupled with an upgraded stock pressure plate to provide higher clamping forces. I purchased these directly from John on his recommendation. The upgraded pressure plate features stronger springs at the outer edges and made little noticeable difference in pedal pressure. ShiftacularUndoubtably one of the coolest things about installing the T5 is the wide selection of sexy shifters. I've never had a problem with the M41 shifter and I'm a huge fan of the correct bake-0-lite shift knob with the roundy white drafting font showing the shift gate. But after checking out a lot of autocross cars and seeing the universe of short throw shifters in Miatas and S2000s I was wishing there was a similar product for our old Volvos. I don't believe there is any real performance advantage to a short throw shifter. They feel like they are making faster, more precise shifts but the net effect probably doesn't get you around a track any faster. They are mainly just really cool - good ones have a shorter travel, shift stops and a very positive engagement - a satisfying click as you move into gear. Shift stops may prevent you from overshifting the transmission during hard driving and well designed shifters ought to hold up to more punishment than the stock setup. Also: they look super-bitchin and make other people jealous. The choices for the T5 are dazzling and cool. There are enough Mustang drivers out there to encourage production of all sorts of aftermarket shifters. The stock T5 shifter should work just fine and can probably be had for almost free - if you are on a budget this would be a great place to save money. The aftermarket staple seems to be the B&M Ripper but there are an avalanche of cool billet shifters and ebay knockoffs of the better designs. I did a lot of research, wading through sketchy internet opinion sites and magazine reviews and finally settled on a company in Georgia called MGW that has a small high-quality product line. Their Mustang shifter was touted as the superior product wherever it was mentioned so I ordered one along with a flash shift knob (impulse buy). The quality of the the piece that showed up was awesome and had an understated, yet bling, orange anodized color on the shift handle. The shift knob shows the T5 shift gates and has a grippy coating. Very nice stuff for the money. It bolts right up to the stock shifter hole with an RTV gasket maker substance and is dead sexy. It is really hard not to shift it through the gates and make motor noises while waiting to get the tranny in the car and fill it with fluid. More stuff to buy

Adapter plate: $150 You need to get an aluminum adapter plate from John at VPD. This is a .75" thick aluminum plate with offset countersunk holed to allow the Ford Trans to bolt directly to the Volvo bellhousing. It's a nice piece that uses the stock socket screws that were used between the M41 and the bellhousing. (Note: Current plates are 1" thick and no longer require modification of the transmission input shaft) Driveline AnglesBefore you start this project you should pay a lot of attention to the stock orientation of your drivetrain. Go to Harbor Freight or Northern Tool and buy a cheapo angle finder and a plumb bob. Before you remove anything you should measure as many things as possible. The angle of the engine as it sits, the distance between the center of the tail of the transmission and the ground as well as each side of the transmission tunnel. Drop the rear of the driveshaft and measure the angle of the flange on the pinion - your goal is to try and get back to this same orientation once the new tranny is in. Use a plumb bob and draw a chalk 'x' on the garage floor at the crank bolt, transmission tailshaft, and pinion centerline - and notice how far these 3 points deviate from a straight line. This is good info to have for later sorting out any drivetrain alignment issues so don't gloss over it (like I did). FlyweightI unbolted the driveshaft, pulled out the cranky M41 and detached the bellhousing. I had a leaky rear main seal that needed repairing and I wanted to inspect the flywheel so off it came. Under scrutiny the flywheel had a few small cracks and one fairly large one on the friction surface. I had already had the flywheel resurfaced and lightened by a few pounds on my previous rebuild and these hairline cracks were a fairly recent development. Consensus was that the flywheel would be OK but I had just gotten a nice check in payment for a magazine article I had written and the thought of reduced rotating mass aft of the crank was too tantalizing... Light flywheels are a controversial upgrade and are poorly understood. Volvo engineers created the stock flywheel with smooth engine transitions and low speed tractability as foremost requirements. The stock disk weighs in at about 24 lbs. and I'd gotten mine down to 21 lbs. by having it shaved by a local machinist (this was the maximum amount of material he was comfortable removing from the part). Mark Riley, my dyno operator, repeatedly told me that my motor was still way too 'lazy' and the best modification I could make to my motor was a lighter flywheel made from aluminum. While the results wouldn't be seen on any dyno graphs it would make a huge difference in how rapidly the car accelerated. A flywheel acts as storage for the motor's kinetic energy (momentum). A heavy flywheel stores more momentum than a light flywheel. A heavy flywheel translates to smoother transistions in engine speed and more resistance to stalling as the clutch is engaged - characteristics that are good for a road car. A heavy flywheel is harder for the motor to accelerate - the mass of the flywheel is the first work the engine must do as it tries to accelerate the car. The effects of a lightened flywheel will be far more noticeable in low gears - faster acceleration, more difficult to modulate, more prone to stalling. A lot of people characterize lightened flywheels as being unstreetable.

Available aftermarket solutions weigh in from 6 lbs - 8 lbs. Anecdotal evidence from Phil Singher and other people whose opinions I trust informed me that the 8lb. flywheel was just fine for the street - only slightly problematic at parking lot speeds and the low gear acceleration was well worth the tradeoff. My autocrossing activity (most of which occurs below 3rd gear to stay within insurance friendly speeds) makes this low gear acceleration even more appealing.

I decided to try and justify the expense by quantifying the dynamic effect of moving from the stock 24lb flywheel to the the 8lb aluminum version. Referring to some of the calculations in this article by David Baker at Puma race engines (read all of his articles if you get a chance) I lifted his calculations and applied my gearing variable and used a simplified assumption that the weight difference between the old and new flywheels was evenly distributed. This is probably wildly innacurate (any function with exponents is more susceptible to bad inputs) but it gives a good visualization of the effects of the flywheel and why I would fork over $425 for it. Assuming that a mass of 16lbs (7.25kg) was removed from the flywheel at an average distance of 3.75" (95.25mm) from the center of the 9" flywheel (the 3.75" figure is an approximation). Using David's formula of M = 1 + (Gr/R)2 where M will be the weight in KG added to the weight of the car and plugging in my gearing:

According to these calculations it will be the equivalent to removing 321lbs from the weight of the car in 1st gear and 120lbs in 2nd gear. Them are some compelling figures for an autocrosser. In addition to the dynamic effects of the flywheel in relation to gearing it makes the motor seem livelier and more responsive. It revs very aggresively and is functionally equivalent to adding more power without messing with the motor - good stuff and worth the money and effort. Driveshaft

The T5 is physically slightly longer from tip to tail than M41+OD it replaces. In my 1800E the distance from the tailshaft of the transmission to the pinion flange was reduced to 44". Measure your own application after the transmission is in place! The original 2 piece driveshaft was too long and needed to have the Volvo flange cut off of the front of the driveshaft and replaced with a Ford slip yoke that will slide into the rear of the T5. I consulted a local driveline guy and he suggested I go to a 1 piece driveshaft. He did not like the idea of having 2 slip yoke connections in the driveshaft. He said there should be no vibration issues provided there are no clearance or angle issues. Sooo I had him make up a new driveshaft for $240 and he had it ready the next afternoon. In order to install the 1 piece driveshaft I had to remove the right rear suspension on the car entirely and jack the axle tube up as far as possible. The yoke slid nicely into the back of the transmission and the length seemed to be appropriate. No obvious clearance issues aside from the central seatbelt bolt which was fixed with some shimming. I also removed a bit of sheetmetal from the foreward section of the driveshaft tunnel with an angle grinder - this gave me lots of room for the first u-joint but may not have been necessary. I ended up dealing with a lot of sensitivity to vibrations in the driveline due to driveline angles. Whether retaining the stock 2 piece + rubber encased carrier bearing would have helped these issues is unclear but even then it would only have masked the core problem of incorrect driveline angles. Gory Details - modifications and installationThis was a hard project for me. There are several parts of the conversion that are not just bolt-it-up sort of operations. I spent a lot of time on the email and phone with John to get the project finished. I'll try to go through all of the steps in a comprehensive way so hopefully things will be less difficult for the next person. Modifications to existing partsTransmission input shaft: Note: Modifying the transmission shaft or input shaft sleeve is no longer necessary with newer, thicker adapter plates. This greatly simplifies the conversion process! The input shaft of the T5 is slightly too long and needs to be shortened. Grinding away on the transmission I just plunked down $1100 for was a little scary but John assured me it was a good idea. I bought an angle grinder, some metal grinding wheels, a pipe cutter, and a flap wheel from the local Home Depot. The main input shaft of the transmission needs to be ground down by .2" and the bevel needs to be duplicated at the new length. I carefully measured this using a caliper and put a piece of masking tape around the circumference of the shaft to keep from marring the smooth surface while grinding. I used some duct tape and other junk to cover the rest of the shaft to avoid getting metal bits in the inner workings while grinding. I carefully ground the length down and then removed the foremost piece of tape and clumsily reproduced the bevel - as far as I can tell it's only purpose is to aid sliding the transmission in through the pilot bearing on installation so I did not freak out. I finally used the flap wheel to polish the tip up as cleanly as possible. Transmission input shaft sleeve: Further back on the input shaft is the sleeve the shaft rides in. This also needs to be shortened by .02" but is a little easier (less harrowing) to modify. I marked the sleeve using my measuring calipers, tipped the unit forward and used a pipe cutter to remove the metal. I flushed the area in the sleeve with some WD40 to remove any stray metal bits that may have snuck past. John suggested removing the input shaft housing entirely for performing this operation. Clutch Fork pivot modification: If you are using an aluminum flywheel you will need to compensate for the thinner flywheel by moving the pivot point of the clutch fork using spacers. I removed the bolt holding the clutchfork in the bellhousing and replaced it with a longer bolt and placed a 3/8" nut between the fork and the bellhousing. (Note: I later found this works but is not an ideal spacing).

Clutch Fork: The Ford throwout bearing is slightly different from the Volvo part. The stock clutch fork needs to have tabs ground down a bit in order to accomodate the larger diameter Ford part. I did this by iteratively grinding and then checking as equally as possible on the 2 tabs. Now you use the special spacers provided by John - slide them over the tabs with the meatiest section positioned towards the engine side of the bellhousing. Consider using some well placed axle grease on these parts to help glue them in place during the install. Slide the throwout bearing into its new perch and admire your work. Transmission Crossmember: See below... Installation NotesMost of the install is very straightforward. It is a lot easier with 2 people. Bolt up the flywheel, install the clutch and pressure plate using your Ford clutch alignment tool, install the adapter onto the bellhousing, bolt the bellhousing to the transmission. Stop! If you have a car friend or SO willing to help this is a great time to test your clutch setup. Hook up the clutch cable to the clutch fork and have a friend sit in the car. Using the alignment tool try to rotate the clutch - ask them to depress the clutch and see at what point the clutch frees up and spins. This is mainly a sanity check but it also helps you spy at what point in the travel the clutch is actually engaging/disengaging.

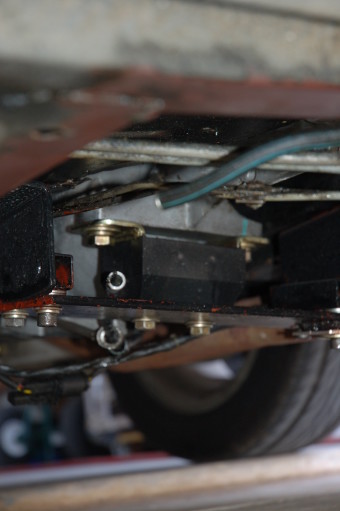

I attached the shifter to the transmission before installing it in the car and put the transmission in gear. I'm not sure the shifter can be installed once the gearbox is bolted up in position. I wrapped it carefully in bubblewrap and rags and dragged the gearbox under the car on a piece of cardboard. You will need to have purchased some big bolts to attach the transmission to bellhousing. Have those ready and hoist the transmission up and into the car. As always this is an enormous pain in the ass and almost killed me. Lancing the throwout bearing and guiding the transmission into place is difficult and after several goes at it I had to call a friend for help - once I had a second person there it took 2 minutes. Now the transmission was sitting attached to the engine with the tail resting proudly on a jack and it was obvious that the transmission mount was going to be difficult. The original mounting holes are way too far forward to be useful and there isn't much else under there to work with. Essentially you are starting off with a blank slate. I purchased a polyurethane Ford transmission mount and started there. I'll describe the route I took and then give some alternatives. This sort of fabrication is over my head - I've no welding skills and no welder to weld with so I towed it to Tim Brigman's shop in Matthews, NC. Tim is a bodyman, not a fabricator, but he helped me work out a decent solution. We positioned the transmission in place where it looked like we had the best clearances for the first u-joint on the driveshaft and started figuring things out. We used two pieces of heavy duty angled steel and welded them directly to the body. We then drilled and welded some nuts on the inside of square steel tubing which was attached to these angle pieces. This gave a clunky but sturdy level surface to bolt up a piece of heavy duty steel plate beneath the transmission. 2 holes were drilled in the heavy steel plate for the Ford mount to attach to. This whole apparatus can be shimmed up and down to find the right driveline angle. I pulled it all apart, painted it with POR-15 and put it back together. It ain't pretty but it works and should withstand direct machine gun fire. This took us many hours and was really hard to do. The mounting solution makes for a very stiff drivetrain - the polyurethane transmission mount transmits more vibration to the chassis but I don't find it to be too harsh for me. I got in touch with John an asked him how he solved this problem on an 1800. He raised the issue of the original drivetrain mounting design of the 1800. The front engine mounts put a light rearward load on the engine - the stock transmission mount has a slight front facing angle. The result is sort of a cradle for the drivetrain. My design only supports the transmission on the vertical plane so the rearward load of the front mounts is never cancelled - possibly putting some strange loads on the front joint of the driveshaft. John's design utilizes an adapter on the transmission to use the stock mount maintaining the original angle along with the original crossmember modified to accept it. He welded bolts to the body to act as studs and allow the crossmember to be removed easily and shimmed up and down. In hindsight this is a much better solution - but a lot of welding wire has me pretty committed to my FrankenMount contraption at this point. Shifter position is close to dead on - I ground a bit of metal (1/8");from the front shifter opening but this may not have been necessary. I used the stock shifter boot along with the stock console although it sometimes bunches up and will sometimes push the shifter out of 5th gear. Looks bloody awesome and shifter ball position ends up very near to original - maybe 1 inch further forward. Driveline angles revisitedIdeally the engine/transmission (driveline) angle should exactly match the angle at the pinion. If the pinion is tipped upward 3 degrees then the engine should be tipped upward 3 degrees - the angles must be identical and parallel. As you deviate from this arrangement you put stresses on the u-joints and create vibration problems that could lead to failures. In my car these occurred at light loads and sounded like the whole gearbox was vibrating and rattling the gears inside of the case - pretty creepy (thanks to Christopher Georger for helping me diagnose the source of these vibration issues).

Supercharger clearance problems: I have had some issues with the supercharger clearing the hood bracing since installing the T5. It was very close with the M41 and the T5 forced me to shift the fore/aft angle a bit. At this point I'm really trying to stuff 10 lbs of shite in a 5 lb bag but I eventually cut away some hood bracing and slotted my motor mount brackets enough to make the whole setup work. The downside of this situation is that I have no room to shim the engine/trans to meet driveline angles so any adjustment would have to occur at the pinion. If you've lowered your car you may find that your pinion angle is tipped downward to be level with the ground or even pointing down. You may notice that the pinion angles and driveline angles are off by as much a 3 degrees. This may not be a problem with the M41 and 2 piece driveshaft with rubber carrier bearing but it may translate into vibrations once the less forgiving T5/1 piece driveshaft are installed. Adjustable Torque Rods Due to the limited range of adjustment available to me on the driveline side I needed to adjust the pinion angle to match the engine/transmission angle. There is no way to adjust the pinion angle with the stock 1800 suspension setup so I needed an aftermarket solution. I set out looking for adjustable torque rods which I found at Kaplhenke Racing for $250. These are really nice pieces with heim joints. They are stiffer and will wear faster than a bushed setup - you can also have them made with bushed rod ends. This car is used mainly for Spirited Driving at this point so I don't really mind the tradeoff. The net effect on ride quality on the street is barely noticeable and I don't feel like it is any harsher than before I installed the rods. You may be able to accomplish this by shimming the driveline - every car is different so you really just have to measure.

I'm still working on tuning the last of the vibrations out of the system. Even with dead-on driveline angles I'm still getting weird harmonic at light load. Check back or email me for resolution. SpeedosI have not sorted this out yet - I know how fast 85mph is on the tach and I guess the rest. :) Test FlightI had many other issues once I got the gearbox installed and secured and full of synthethic ATF. Turns out you need to plug the speedometer drive gear hole with something or else you will quickly lose ATF. I ran up to the Ford dealership and purchased a housing with an electronic sending unit to plug it and possibly accomodate an electronic speedometer in the future. An incorrect driveline angle pushed the nose of the engine too close to the electric fan (unbeknownst to me) and totally lunched it once I got the motor started. This single fan has been replaced by a set of smaller Deralure pusher and puller working together. After that my starter decided to give out and remain engaged with the new flyheel after the engine fired. A used 740 starter took care of that issue. The 740 starter is actually a terrific upgrade. It's easy to find, lighter and it spins the engine around faster than the stock B20 starter. Lots of creative swearing and wrench tossing figured into these obstacles. With these issues resolved I got the motor warmed up and went for a drive. The first thing I noticed was how much more lively the motor was with the lighter flywheel. Jabbing the gas in neutral is very awesome - it revs freely and quickly like a racing motor. The clutch slipped in smoothly and I drove it around a bit. The lower ratios feel very close to the M41 and gear changes are positive, smooth, and silky. There is a bit more noise from the transmission (reverse is particularly whiny) but nothing to worry about. The shifter is the slickest thing ever and I change gears often without needing to. I pushed it out onto a highway and got the speeds up to highway cruising and found that the .68 5th gear is very long. You must rev 4th to 4000rpm before shifting or you will feel very bogged down on getting into 5th - I imagine this would be far more pronounced in a car without a supercharger. I'm glad I steered clear of the Ford Racing gearbox with the .63 5th gear! CruisingYup, the new gearbox sure is nice. Smooth synchros and 5 real gears is fantastic. After working out my crazy harmonic issues the car is very smooth. 5th gear is loooong and too far away from 4th but it does keep the revs down for high speed cruising. The shifter is beautiful and fun to operate with satisfying clicks from gear to gear. I have no tractability issues with the flywheel and I'd recommend it as a no-brainer improvement if you are doing any clutch/tranny work and have performance goals. My clutch begins to engage as soon as the pedal is lifted rather than further up where it would normally be. I believe I can fix this by readjusting the shims on the clutchfork but that means removing the transmission again and I'd like to wait a while for that - it seems to be improving as I wear in the disk a bit so it may solve itself. The real dealNow it was time to really put this rig to the test. I've been to maybe ten autocrosses with the supercharger and I was just getting used to modulating the power of the car and turning in respectable times. I had been short shifting 1st at every event to accomodate the failing M41 and diminishing the drama of launches. I'd had very little testing time with the car on the street and I was pretty excited to give it a go at an event with the Central Carolinas Region SCCA at Knights Stadium in Charlotte. At the start I revved the motor to about 3000rpm and dropped the clutch - the new disk grabbed smoothly without complaint and jerked the car off the line. A brief dip in rpm quickly turned around and the new flywheel began earning its keep. Both rear wheels spun up past the edge of adhesion up to redline sliding the car sideways around the first turn. The car shifted obediently into second. A no-frills 1->2 shift was a big win for me - all smiles. Between the magical new acceleration conveyed by the flywheel and the early clutch engagement my entire first run and most of my second were spent keeping the car under control rather than concentrating on a strong run. By the 4th run I was really enjoying it and figuring out how to direct it towards good times on the clock. A huge bloody improvement. Post MortemThis was a difficult project for me with very satisfying end results. If I knew then what I know now I would have seriously considered rebuilding the M41. The vibration issues took a lot of time and ruined the appeal of the gearbox for a while. But - hopefully the above breakdown of costs and tinkering will soften the blow for the next shade tree Volvo mechanic who attempts a T5 conversion. Current adapter plates remove the need to modify the gearbox itself and most of the other details are well documented. In the end I'm very very happy with it and glad I did it. 2007?Suspension reinforcement project, R-compound tires, boost increase targeting 200whp, missile launchers and maybe some A/C since I just moved to Austin, Texas. 2007-03-01 sberry |